Pumps for Limestone-gypsum wet FGD (Flue Gas Desulfurization) Process

- 13 Feb, 2022

Ⅰ. Principle

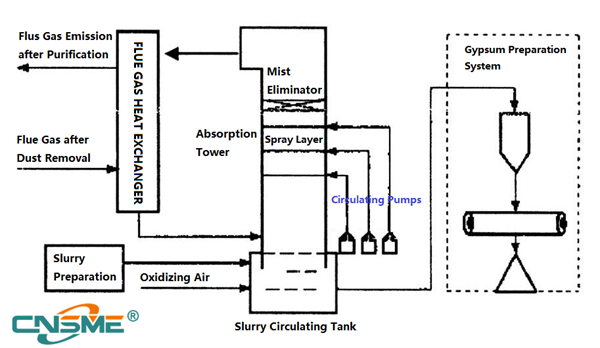

SO2 is one of the main air pollutants and an important control indicator of industrial waste gas pollution in China. At present, all coal-fired machine units in China have implemented flue gas desulfurization projects, among which the dominant desulfurization technology is limestone/gypsum wet flue gas desulfurization (WFGD). In this process, limestone slurry is used as an absorbent, which is in countercurrent contact with the flue gas in the desulfurization tower and then is fully mixed. After the SO2 in the flue gas reacts with the absorbent, it chemically reacts with the oxidizing air that is blown by the oxidizing fan to form gypsum.

There is a slurry tank at the bottom of the absorption tower, and the fresh absorbent is pumped into the slurry tank through a limestone feeding slurry pump; under the function of the agitator, it is mixed with the existing slurry in the slurry tank; then, the slurry circulating pump will raise the mixed slurry to the spray layer and spray it down to contact with the flue gas in counter-current flow. Efficient and timely replenishment of fresh absorbent is critical throughout the whole process. If the supplementary amount is insufficient, it is difficult to guarantee the desulfurization efficiency; if the supplementary amount is too high, it will reduce the utilization rate of the absorbent, and affect the quality of the desulfurization by-products. Therefore, limestone slurry pump control is an important part of FGD operation.

Ⅱ. Pumps required by the processing system

1. Limestone preparation system

2. Pump for an absorption tower system

3. Flue gas system

4. Pump for gypsum dewatering system

5. Pumps for discharge systems

6. Pumps for wastewater treatment systems

Except for the flue gas system, the above systems will all require slurry pumps. In the absorption tower system, the injection volume is relatively large, so the diameter of the pump is relatively big. The pumps in this part are large-scale special pumps designed for desulfurization, and the pumps used in other systems are our commonly used small and medium-sized slurry pumps. According to the situation of the slurry, the material selected of the flow parts is both wear-resistant and corrosion-resistant.

Sketch of FGD System

Circulating pump for FGD system being used at Site